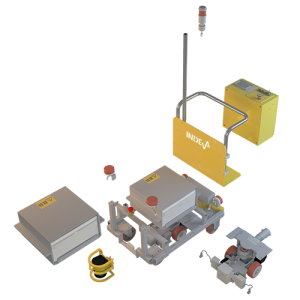

A custom built INDEVA AGV is designed specifically to meet special site & operational requirements regarding structure, layout, size & program.

A custom built INDEVA AGV is designed to your exact specifications using either modular pipes & joints from our INDEVA Lean System range of components or a steel base structure.

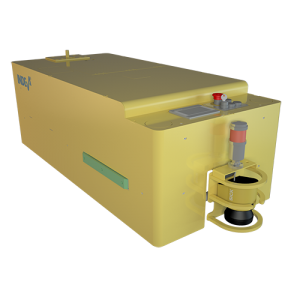

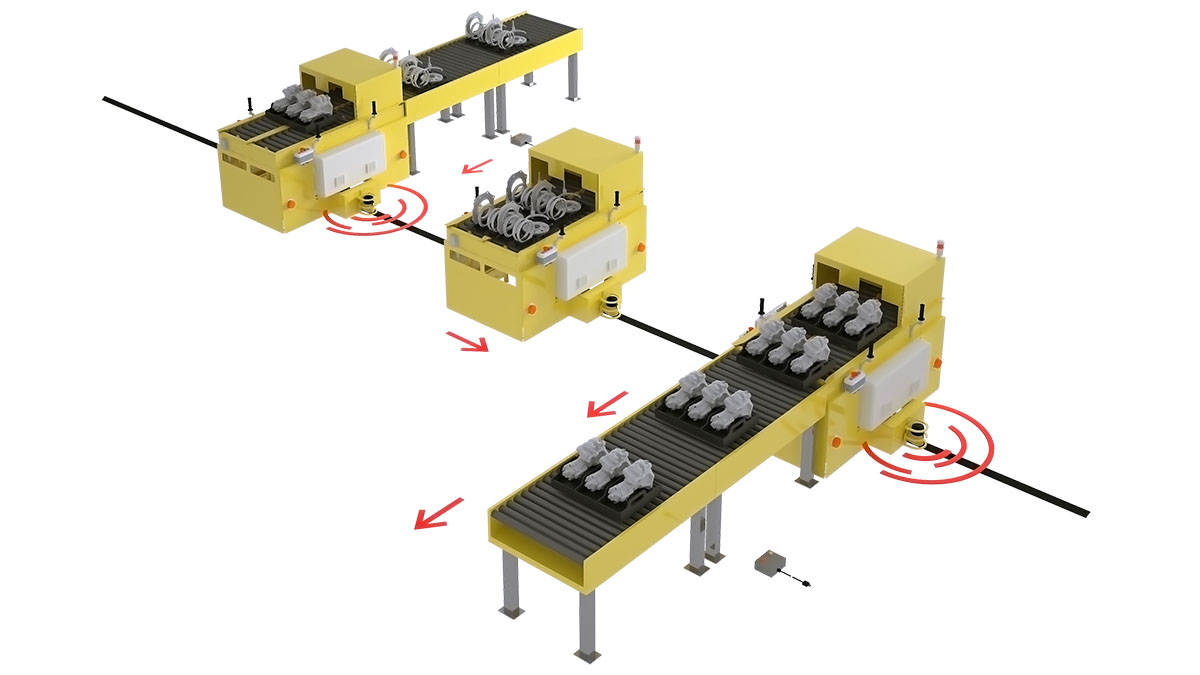

The INDEVA AGV shown above is complete with power driven rollers for uploading large containers from the conveyor line that carries material between the warehouse & assembly line. It can carry loads up to 1500 kg.

An INDEVA custom gravity AGV is used to transport boxes & small containers in both directions between the warehouse & assembly line. The loading/unloading of the boxes from/to the AGV is carried out with a completely automatic & simple mechanism using gravity to slide boxes from the AGV to the rack & vice-versa.

We study in depth your material flow & requirements, then design solutions that best suit your product type & work cycles. We provide the complete program allowing the AGVs to perform all the required tasks.

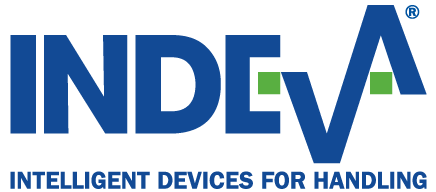

The above shown custom built INDEVA AGV is equipped with custom made power driven conveyors, matched by similar conveyors at the load & offload positions. On arrival at correct location, the AGV establishes contact with the conveyor using Wi-Fi. This sets both powered conveyors rotating at the same speed, so providing a smooth, controlled transfer of product. Potential applications are the transfer of heavy loads & fragile materials.