CASES

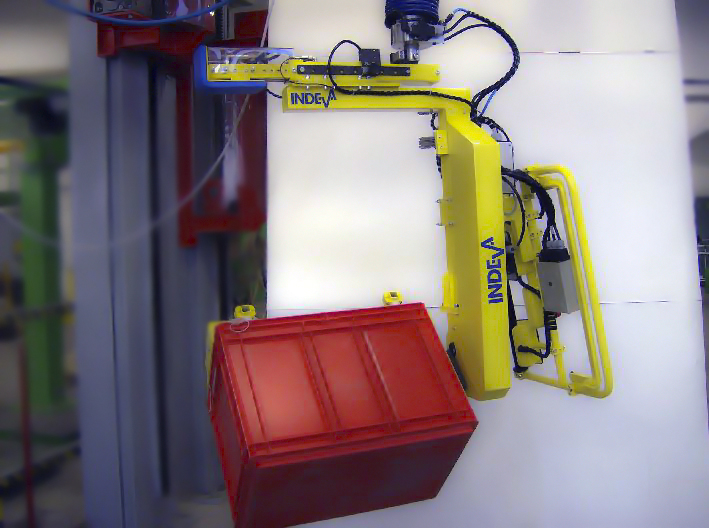

With an INDEVA® you can handle cases of different SIZES, WEIGHTS & EMPTY them in a safe & ergonomic way. In fact, the INDEVA® manipulator allows the tooling to remain safely still whilst the load weight is changing: no jerks, no bouncing thanks to the AUTOMATIC load weight sense & balancing, typical of the INDEVA® manipulators.

The INDEVA®s can be equipped with an end-effector with tilting device for turning cases up side down in order to empty them.

A well known publishing company needed to improve productivity & find a quicker and safer way to lift cases full of books from the pallet & move them unto the conveyor. Each case weighs about 60 kg. and the operation is repeated several times a day; the manual handling was too slow & unsafe; a traditional electric hoist wouldn’t have made it faster enough.

Moreover the handling operation needed to be very smooth & user friendly, as well as ergonomic & safe for the operator. An hoist compels the operator to keep the up – down button constantly pressed, with possible hazard to his health (Carpal Tunnel Syndrome), and it may discourage him to keep using the hoist and induce him and carry out the handling operation manually again.

The only ideal solution to this demand has been two industrial manipulators INDEVA® for handling cases with end-effector suitable for gripping & lifting 3 cases at a time.

Handling Cycle

- PICKING the cases from the pallet, short side of the case facing the operator (the cases are tangent to each other.

- SELF BALANCING END-EFFECTOR for handling 3 plastic cases weighing about 60 kg each for a total weight of 180 kg.

- The grip is CARRIED OUT by means of two pairs of jaws that grip the cases laterally along the longer side.

- The jaws position is ADJUSTABLE according to the number of cases to pick together (from 1 to 3).The end effector is equipped with a couple of ergonomically designed front handles, of which one is a fingertip in line force sensing handle.